I am so close to getting this right now... but not quite yet.

Clean a piece of copper board with thinners & some mutton cloth or a rag.

Use scotch bright bad to clean the copper to a shine. The scotch bright pad is very abrasive & leaves a thin layer of copper partials all over the board. You wont be able to see them but wiping the board down again with some cloth will show... I know this because i tried *this* method of toner transfer & the transfer was patchy... I rinsed the board in water, then wiped it down again.

Turn you iron onto the hottest setting. It's probably better to use a NON-STEAM IRON, but mine was a steam iron, so I had to drain out all the water first.

Print the positive mirror of the board you want. Use the highest print settings. I used standard copy paper & a laser printer.

Use masking tape to tape on end of the print out to the board, then stretch the other end & tape it. Tape everything so that it is tight. this ensures that there will be no air bubbles in the paper when you iron it.

Center the iron over the board, & leave it there for 2 minutes.

Use your 2 minutes to fill up the kettle & boil the water.

Iron the board in every direction putting pressure. You can stop ironing once you hear the kettle has boiled.

So after a total of 5 minutes of ironing my board looked like this. I left it to cool for a bit while I...

Plugged up the kitchen sink & emptied the kettle into the sink.

Let is sit in the boiling water for about 13 minutes, you should be able to see the tracks through the paper.

Rub the paper with your finger. the paper should easily dissolve & come off.

- Don't rub in the same spot for too long. The toner tracks will break.

- Don't rub too hard. The toner tracks will break.

- Don't rub too fast. The toner tracks will break.

- Once there as some paper balls, shake them off so that the don't roll over the board again. If you don't, the toner tracks will break.

Here you can see the paper balls forming.

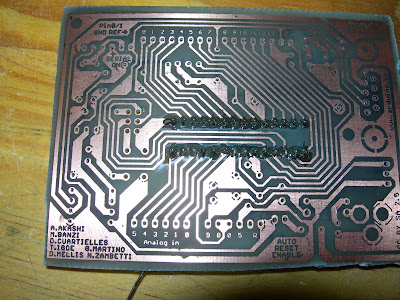

After all the paper is off, this is what the board looks like. Some of the tracks were damaged, so...

I tried my best to touch them up with a permanent marker, but the tip was to fat!

pore half a bottle of ferric chloride in a paint tray.

Submerge the board in ferric chloride. This photo angle shows there was still some paper residue on the board!

I wish i had a shake table! The fumes were so strong! I sat there for 45 minutes shacking the paint tray to agitate the solution in the hope that the reaction would go faster. I Did this for 25 minutes which was not enough. so then I checked on a 5 minutes interval.

Put on a glove & rinse the board in a separate paint tray containing tap water.

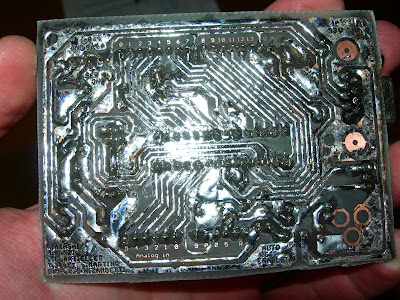

Once my board looked like this I decided it was done etching. In some places it was over exposed & the copper tracks were eaten away. Dry the board with a paper towel.

Pour the ferric chloride back in the container. The solution becomes weaker but that's ok. When this solution begins to take too long to do reactions I will try the pool acid & hydrogen peroxide! At least that is clear. (so you can see the reaction happening)

Take some thinners & a cloth & wipe off the toner, leaving the developed PCB. As you can see from this picture there are broken tracks everywhere. The next day, the board looked like it was oxidizing again. I should probably mention it has been raining a lot lately & there is a lot of moisture in the air.

So if anyone has read this & has a working method for toner transfer PCB etching & wants to save me some trouble, please let me know! Photos of each step would be really nice, but at this point I would settle for very explicit, clear & unambiguous instructions.

And Yes, I am aware that the exposure time for the board in the acid depends on:

- the size of the board

- the amount of exposed copper that needs to react

- the strength of the acid

- the temperature of the acid - (there is no ways I will heat up any acid! That's where i draw the line)

This is painful!

no photos of that needed.

no photos of that needed.

Because the rats nest is such a mess, I am now going to have to de-solder the IDL headers and hard wire cat 5e cable in its place, this will make it easier to connect to the arduino break away shield and easier to route the wires.

Because the rats nest is such a mess, I am now going to have to de-solder the IDL headers and hard wire cat 5e cable in its place, this will make it easier to connect to the arduino break away shield and easier to route the wires.